By: Editorial Staff, Date: October 3rd, 2022

Today, manufacturers are faced with tremendous disruptive technological challenges that require them to rethink how they operate as a business. To compete in the new digital industrial age, manufacturers must embrace new technologies and processes that will drive their businesses forward.

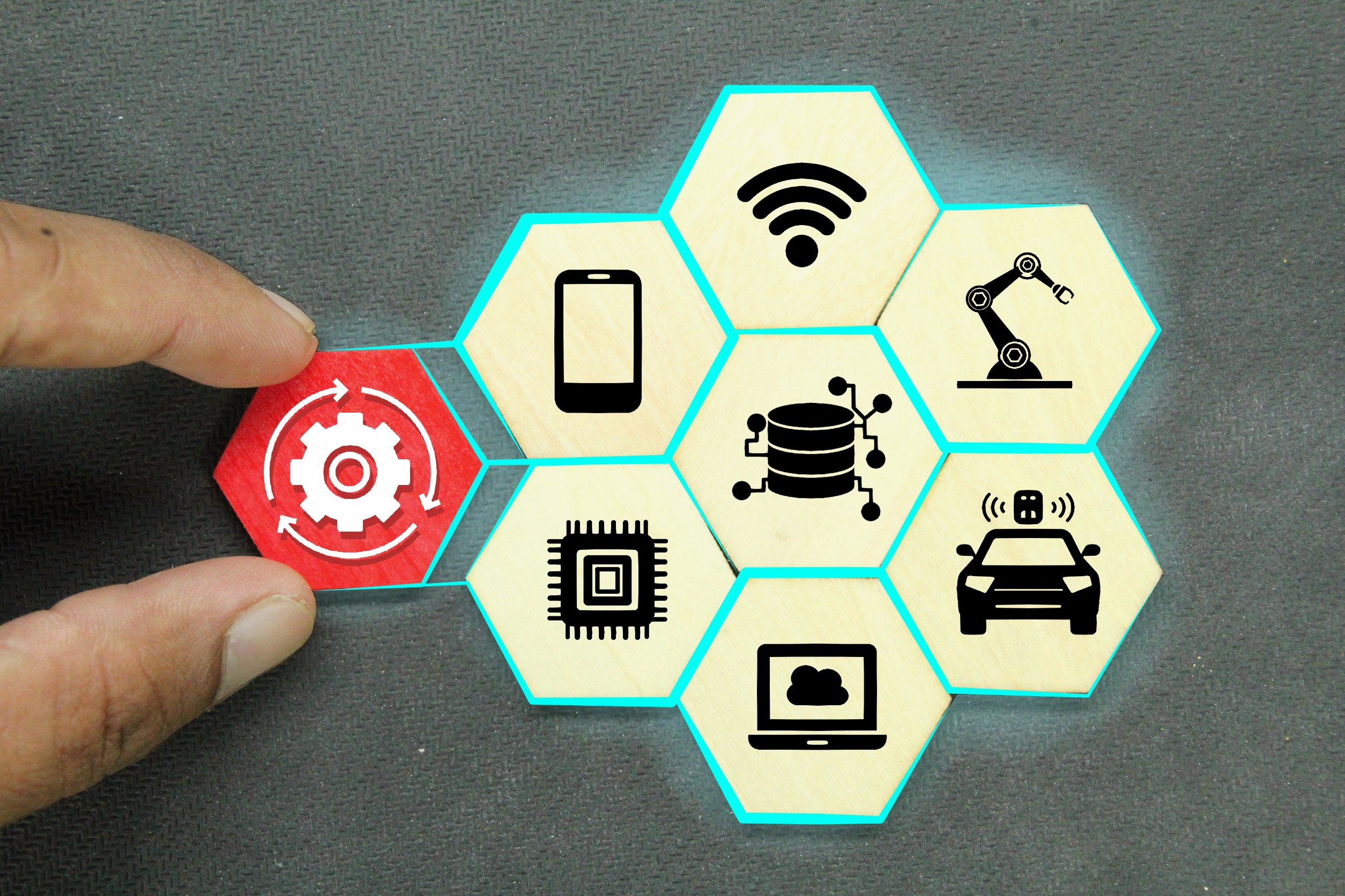

With The Industrial Internet of Things (IIoT) becoming increasingly popular for smart manufacturing, manufacturers now have the opportunity to create a Digital Twin of their operation. This enables them to monitor performance, streamline maintenance, and optimize uptime.

Read on to discover 6 smart manufacturing IoT strategies that will help you accelerate your manufacturing operations and stay ahead of the curve.

1. Establish a Foundation with IIoT

The Industrial Internet of Things is all about bringing systems and machines together to collect and analyze data in real-time. By connecting sensors, machines, and other assets, IIoT allows you to automate business processes, reduce downtime, and increase productivity.

This digital transformation can be a challenge to implement, particularly for manufacturing companies. But it’s essential to build a strong foundation for digital transformation with IIoT before you can integrate other technologies and optimize operations.

IIoT for manufacturing provides a wide range of benefits. These include increased asset uptime, optimized resource utilization, reduced risk, and increased productivity. It also offers plenty of opportunities to expand its functionality with other digital technologies. Many of these can be integrated into the system to drive business benefits.

2. Streamline manufacturing operations

To streamline operations, manufacturers can use IIoT to build a Digital Twin of their operation. This is essentially a virtual model of the entire production process that’s run by software. The Digital Twin can be used to monitor real-time data and detect anomalies along the way.

You can also use IIoT to optimize resources, such as energy and inventory. For example, by connecting sensors to machines, sensors will be able to alert you when you need to reorder stock. Or by connecting machines to a central database, you can schedule maintenance at the right time.

With smart sensors, you can be alerted when the environment or an asset is out of the acceptable range. This can help you to prevent unplanned downtime and costly repairs.

3. Roll out autonomous robots

Robots are essential to many manufacturing operations, and today’s manufacturers are now able to automate repetitive tasks using robotic process automation (RPA). RPA can be used to simulate manual processes, such as data entry or asset management, with various workflows.

The benefit of using RPA is that it can be applied to a wide range of industries, including e-commerce, financial services, healthcare, and retail. RPA is particularly beneficial for the manufacturing industry. It can be used to monitor and control autonomous robots to perform complex and time-consuming tasks.

This enables manufacturers to automate processes that are currently performed manually, such as tracing faulty parts. It also has a wide range of benefits. These include faster throughput, better accuracy, reduced errors, and increased competitive advantage.

4. Enable real-time visibility

To achieve real-time visibility across your entire operation, IIoT can be integrated with data analytics. IIoT will help you to visualize and understand your data in real-time. It’s important to have the right software that allows you to see everything in one place.

With data analytics, you can monitor performance, traceability, and risk. You can also monitor energy efficiency, machine breakdowns, and inventory. This type of visualization helps you to make smarter decisions and take more informed actions in your business.

A well-managed operation gives you a competitive edge. By using data analytics to increase visibility across your operation, you can reduce errors and maximize productivity.

5. Leverage cloud computing

As the number of sensors and machines increases in the manufacturing process, it becomes more challenging to manage the data effectively. Companies can now use IIoT with cloud computing to store, manage, and analyze data in real-time.

This can be a significant advantage for manufacturers as cloud computing has become increasingly important in recent years. Cloud computing allows you to store data in the cloud, which allows you to expand your business.

You can also manage data and software remotely, which will help you to scale and grow efficiently. This will also allow you to use a centralized database to organize and store all your data.

Cloud computing can also be used to integrate IIoT with other systems, such as asset management and workflow management. This will help you to manage data across systems and improve business efficiency.

6. Leverage on HMS communication expertise

With more than 30 years of experience in industrial communication and 30% of the staff involved in Research & Development, HMS is in the business of constantly pioneering new technology and easily customizable solutions for device manufacturers, machine builders, and system integrators/end users.

Discover industrial IoT solutions to grow your business the smart way. Contact HMS to learn more!

——————————————————————————

Sources:

Smith, A. (2022, August 12). How to Get Started with Smart Manufacturing and IIoT: Part 1. International Manufacturing Technology Show

https://www.imts.com/read/article-details/How-to-Get-Started-with-Smart-Manufacturing-and-IIoT-Part-1/1635/type/Read/1

Raczy, J.P. Z (2022, August 11). Digital Twin and Simulation: Replicating Industrial Systems to Enable Improvement. Automation.com Blog.

https://www.automation.com/en-us/articles/august-2022/digital-twin-simulation-industrial-systems-improve

Parikh, S. (2022, July 20). The Role Of Automation In The Manufacturing Industry. Nividous Blog.

https://nividous.com/blogs/rpa-in-manufacturing-industry

Corallo, A., Crespino, A.M., Lazoi, M., Lezzi, M. (2022, August). Robotics and Computer-Integrated Manufacturing. ScienceDirect Journals.

https://www.sciencedirect.com/science/article/abs/pii/S0736584522000205

Rosso, R.S.U. Jr (2022, May 31). Transition towards Smart Factories. Informa Journals.

https://www.tandfonline.com/doi/full/10.1080/0951192X.2022.2080451